3D Printing Industry reviews the FlashForge Creator Max 3D printer.

Designed by renowned manufacturer FlashForge, the Creator Max is a dual extrusion FFF system based on the widely successful Creator Pro. With a price tag of $879, the machine is aimed at enthusiastic hobbyists and SMEs looking for affordable multi-color, multi-material rapid prototyping.

Following the FlashForge formula, the Creator Max is characteristically sturdy. Its robust 15kg metal frame stands at 320 x 467 x 381mm, meaning it will require a sizable dedicated workspace. The modest 227 x 148 x 150mm build chamber is completely enclosed provided the optional acrylic overhead cover is used, allowing for precise temperature control. The front of the printer houses a 3.5” full-color touchscreen while the back is home to two external spool holders. Connectivity options include a USB port, an SD slot, and Wi-Fi.

FlashForge has chosen to house the dual extruders in a single printhead, meaning its print speed may be limited as a result of its weight. It works on a cartesian coordinate system, whereby the printhead moves on the X and Y axes, and the bed moves along the Z-axis. The machine has a maximum nozzle temperature of 240°C and a maximum bed temperature of 120°C, claiming it can print with filaments such as ABS, PETG, Wood, and PVA.

Setup and first impressions

Straight out of the box, we see the various quality of life features on the body of the Creator Max. The thoughtful inclusion of the LED strips on the interior of the build chamber enables in-the-dark printing while a set of handles on the sides of the frame make for easy carrying. The Z-axis also has a 10mm guide rod which allows for smoother bed movement.

Looking at the build plate, we see a 6.5mm aluminum alloy platform which should be resistant to any deformation while providing excellent temperature distribution. It’s covered by a matte plastic sheet for better print adhesion. One thing to note is that the build platform is not removable, so a bit of elbow grease may be required when removing a not-so-cooperative print.

The bed leveling process is manual but guided by the colorful touchscreen. The Creator Max has a three-point leveling system, whereby three screws under the build plate control its height. The user is required to adjust these screws until a slight frictional force is felt when sliding a leveling card under the nozzle. While it doesn’t take a rocket scientist to level the machine, we thought it could do with a quick auto-level sequence before every print.

One thing we did notice upon closer inspection was the lack of adequate cooling on the printhead. When two nozzles are this close together, they can sometimes affect each other’s temperature profiles as they essentially act like radiators. In the case of dual material prints, this can result in oozing and blockages in the unused nozzle. On the printhead of the Creator Max, the two extruders share just one fan outlet, meaning the space under each nozzle does not have its own dedicated cooling system – a major concern given the enclosed build chamber.

FlashPrint slicing software

As with all of its 3D printers, FlashForge provides its own slicing software for use with the Creator Max: FlashPrint. Much like the FlashForge logo, FlashPrint has a distinct blue and grey color scheme which is maintained in all of its menus. The slicer has a very sleek look with minimal UI elements, leaving plenty of viewport for STL manipulation.

When it comes to functionality, the basic translation, rotation, and rescaling functions are clearly labeled and intuitive. Alongside them is the ‘extruder’ button, which allows users to select which extruder they would like to print with. When it comes time to support the model, users are given the option to choose between two geometries: linear and treelike. The supports can be auto-generated or manually added in a point-and-click manner (or both).

For users that are more familiar with slicers and 3D printing in general, FlashForge has included an expert mode. In expert mode, the full range of parameters is available, including temperatures, speeds, infill, cooling, and even the LED color. When compared to other proprietary slicers, FlashPrint stands out for its ease-of-use and comprehensive set of features – a testament to FlashForge’s experience in the FFF marketspace.

Benchmarking the Creator Max

Promises and claims aside, it’s time to see if the Creator Max is really worth its price point. We put the machine through its paces with 3D Printing Industry’s comprehensive list of print tests, all designed to test some aspect of the system’s printing capabilities.

We kicked it off with the test files provided by FlashForge itself on the SD card. We figured if the machine can’t even handle the gcode optimized by the manufacturer, it would raise some major red flags regarding the quality of the system.

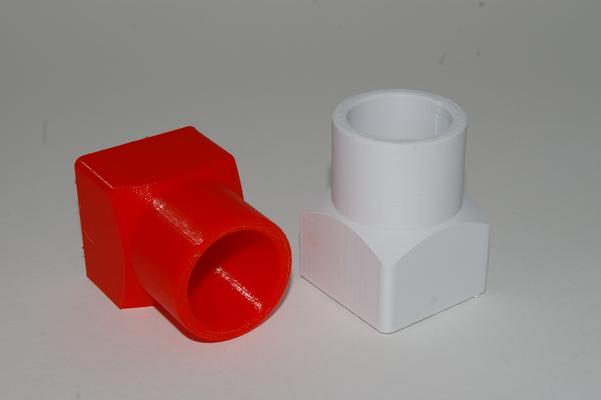

Fortunately, there were no problems here. The red block was printed in PLA on the left extruder while the white block was done in ABS on the right extruder. As expected, both prints ended up virtually perfect with smooth surfaces and no artifacts – no surprises here.

We then moved onto the tower test, which tests the machine’s ability to print tall, thin structures. With this model, we stretch the tower out to the maximum Z-height the printer is able to manage (in this case, 150mm). Cartesian-based FFF systems tend to show their cracks with taller models due to the vibrations and resultant shaking caused by the stepper motors. If the printer’s frame isn’t very robust, this shaking can result in obvious layer lines towards the top of the printed part where the effects of inertia are greatest.

Unsurprisingly, the Creator Max shines in this area. FlashForge frames are generally very sturdy in nature, and this machine is no exception. It may be fairly boxy in appearance, but the full-metal body does a great job of dampening vibrations. A close inspection of the tower model reveals seamless layering and smooth walls.

Next up was the architectural test, which gives us an indication of the system’s ability to print fine details. This time, we chose to go with Helsinki Cathedral due to its abundance of windows and thin pillars, making it quite a tricky model for even the best FFF systems.

The result here was actually pretty great. The edges of the cathedral didn’t suffer from delamination or warping issues, and the mid-19th century architecture held strong. The Creator Max was able to preserve the beauty of Helsinki Cathedral (even if it was in cheap PLA).

Moving on, we had the Creator Max print a differential gear system. This test is perfect for determining the dimensional precision of a printer as it will only assemble easily and operate smoothly with tight tolerances.

While we did notice some defects on some of the surfaces, they weren’t so severe that we couldn’t sand them off in post-processing. We eventually ended up with a system that worked well with minimal frictional resistance. The parts are precise enough that it can be assembled with ease and used as a functional piece.

Our penultimate test on the Creator Max was with flexible TPU filament, a material that typically extrudes at 220 – 250°C.

The machine handled the flexible thermoplastic very well. Our cube had no imperfections and maintained its flexibility through the printing process. It’s able to return to its original shape despite significant deformation and crushing – a win for the Creator Max.

Finally, we come to the dual material print test, which is perhaps the most important one for any dual extrusion machine. Unfortunately, our fears concerning the poor printhead cooling materialized in this case.

Every time we attempted a bi-color print, one of the nozzles clogged, ruining the print in the process. To unclog it, we were forced to disassemble the entire printhead and go in there manually with an unclogging tool. A dedicated fan outlet leading to each of the nozzles would solve this issue, so we’re unsure what exactly led to the peculiar design choice. This is a system that relies on precise temperature control, and the dual extruder setup on the Creator Max is simply not built for it.

The verdict

Playing around with the FlashForge Creator Max has been a rollercoaster ride to say the least. As per the company’s history, the body of the machine is built like a truck, and features a multitude of design considerations that make it a worthy addition to any workspace. Users are given a whole host of connectivity options (including the coveted Wi-Fi) and the company’s own FlashPrint slicer works like a charm. FlashForge has even given the Creator Max its own internal hard drive, meaning users can store gcode locally for future printing.

The machine’s print quality, at its core, is actually well worth the price point. The only caveat is that you can only use one extruder at a time due to the poorly designed cooling system housed in the printhead. Attempting to pull off dual material prints will likely result in oozing and frequent blockages, all while having to listen to the noticeably loud drivers.

At sub-$900, the machine actually does what it should. It just seems like FlashForge has attempted to pack too many features into its budget punch. The Creator Max makes more promises than it can keep, and falls short of expectations as a result.

Buy the FlashForge Creator Max here.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the FlashForge Creator Max. Photo via FlashForge.