In a conversation between TCT and Xact Metal at TCT 3Sixty, CEO Juan Mario Gomez [JMG] outlined his company's intentions around making metal 3D printing affordable for small and medium businesses, as well as educational institutes. Weeks later at Formnext, the company announced the launch of the XM200G platform in line with a price reduction of the XM200C machine, and TCT paid Xact Metal another visit to discuss both developments and more.

TCT: At Formnext, Xact Metal announced the launch of the XM200G metal 3D printing system at $90,000, while reducing the price point of the XM200C to $65,000. Can you explain the motivation for these developments?

JMG: We're trying to really bring the pricing points down so that the market is increasingly more accessible to more and more people. The value that you get in powder bed fusion is very high, the pricing points are very difficult for many customers, because it's just only very rich companies or rich universities that can afford this technology. And what we're trying to do is make that more and more affordable. So, we've done two things. One is to introduce a new pricing point for XM200C. This now gives you a high quality part, it's equivalent to any part that you will see from any other machine in powder bed, but it starts on a pricing point in the United States of $65,000. And so, it's a very attractive price point to a market that we think has yet to be tapped in powder bed. And we think that market is there.

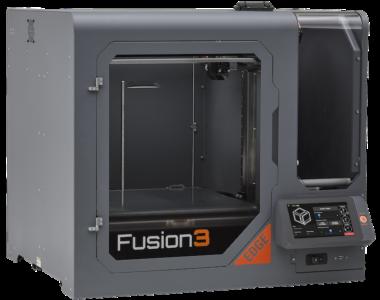

That machine does a great job, but when you're trying to put the kind of throughput or you want more flexibility in terms of power, that machine is limited in that sense, which is fine. So now we've introduced the XM200G, that's a very flexible machine in regards to configuration. So, it starts at the same price that the XM200C used to start ($90,000). It's the same price as before, but you can get a 100 watt laser, a little bit larger build volume at 150 x 150 x 150 mm, but it starts at $90,000. It uses a traditional galvanometer system/ F-Theta lens combination, but we were not cheap on the galvanometers, we were expensive, high-performance galvanometers, good quality lenses [and] have a large build volume. And so it allows us to print at very high speeds and the option for the customer to have 100, 200, 400 Watts also allows it to have a reactive/ non reactive capability. And the last thing that's very important, that's very exciting, it allows them to have an option for multiple lasers, so you can have either one laser option or two laser option and that option costs [another] $65,000. So, now you can start your journey into this volume, either as a customer that has a lot of volume, where printing time is now important for them, or a university that wants to explore multiple lasers at one time. It's really a nice machine, very easy to use, very simple, same architecture as before, but now in a galvo-based system.

TCT: Why was now the right time to reduce the price point of the XM200C?

JMG: Yeah, so great question. Today, everybody's increasing pricing because of supply chain issues and we think that that's the wrong way to go. For this industry, metal powder bed needs to come down in price for it to be widely accepted and adopted. And we now have four years of working with 200C, we understand what's working, what's not working, and we understood to take some costs out. So now instead of saying, we introduce the 200G at the same pricing points, we were able to find, how do we take cost out of that? And we brought the cost down on the 200C, and that saving in cost we bring it to the customer on pricing.

TCT: Obviously it’s important that the price points come down, but how challenging is it for vendors to do that?

JMG: We actually think that we're completely okay with the pricing points, we feel it's a very sustainable pricing point. If anything, we want to continue that journey to bring it down even further, so our aim is to make this pricing more and more affordable. When plastic 3D printing started, the pricing points were high. Now you see the pricing points are incredibly more affordable. And there's no reason that in metal powder bed we can't do that. Our focus has to be there's a space for machines that print things for rockets, and critical missions, there's of course, a high throughput production environments and there's a space for a machine that is more where we are playing. The limitation is not that difficult, we are finding that there is customers that have limited budgets and we also find that there's also customers that have the money but doesn't want to take the risk. So they can start the journey here and do it in a way that's either affordable or less risky.

TCT: By introducing the XM200G, do you expect users of the XM200C to upgrade or are they targeted at different users?

JMG: We think that with both machines we're able to now explore a range of pricing points that allows us to meet a range of different application problems. With 200C we see a person really starting their journey with a limited budget into metal 3D printing. We see workforce development being very applicable, because now you have not only universities, but also training centres and technician schools to be able to afford the machine. And you see smaller shops being able to start their journey and as they start getting busy that they can upgrade to a larger machine, either from us or from somebody else, but they can start that journey at a pricing point that's not as difficult anymore. And then this one, just if we know that customers are already going to be higher throughput, then we know to start the journey with this machine.

TCT: What’s the significance of the XM200G’s galvo-based system?

JMG: We get a lot of benefits with the XY gantry system, we get benefits in regards to positional control, we get benefits in regards to drift, we get benefits also in regards to being normal to the powder bed. Because we get all the benefits, the machine is very smart. So you can see that we don't have to be very high to have the normality of the beam that you need to have with a galvo, we're able to do that with a very small package. The problem with that machine is we have to carry heavier weights, we have to move longer distances, which makes the machine a little bit slower. And so when you have a feature that's very precise, we may be 60-80% of the speed of the Galvo. That's okay for somebody who's not sensitive to printing time: a training centre, a prototyper, that's not okay when you have a need for speed, like a machine shop, a tooling shop, a dental bureau, you can't afford that type of speed because then throughput starts getting very important. If you're supporting the production line at a large customer through the tooling department, you can take three days printing that tool, you need to print it in one day. The XM200G prints parts typically a third faster than the XM200C with one laser. Now with two lasers, it's even faster, so it just gives the flexibility to a customer to enter, but still at a very attractive price point.

[With] both lasers moving, this gives us the ability to move very quickly to allow a customer to get the parts really quickly, it's very important. For $150[,000] you can have a two laser systems at a 100 watts. That's incredible in today's pricing points. So, what our mission continues to be is to establish a new level of price and performance in powder bed metal 3D printing. In powder bed, when you have a need for critical part, you can't sacrifice part performance, this is just the way to go. But the pricing points need to be at the right level. And that's what we're trying to do.

TCT: When should users opt for the higher wattage lasers or the lower wattage lasers?

JMG: With a higher wattage, you may be able to do reflective metals like coppers and aluminiums that you need more power to get to the metal, or you able to do thicker layers. So instead of doing 30 micron layers, you may be able to do 50, 70 micron layers, therefore increasing throughput to speed, and you need that higher power to go through.

TCT: What materials are compatible with the XM200G today?

JMG: The materials will be the same as that that you see on the 200C. So it's the same materials that you see available on a 200C or any part of that system, and that we have typical nonreactive metals like stainless steel 360, 17-4, and now we also have maraging tool steel. And we started to do also 718 and 625, so these are very typical non nonreactive powders, we are doing also bronze and copper. In this machine, bronze or copper will be available. Bronze and copper require more energy to get through, so it's important that we have high throughput. And of course, they are supporting reactive and non reactive metals. So reactive metals we'll support aluminium and titanium. But for titanium and aluminium, this machine has an option, instead of having a two window option, it has an option to have a glove. So you're able to work in a space that's flooded with argon and oxygen and not have any corrosion or oxygen come into your reactive metals.

TCT: With this material offering, what types of applications do you see users taking advantage of?

JMG: We talk about three personas. We talk about a person starting the journey from plastic to metal. That's still a very high focus for us and you see some of these machines there. Then you also see the tooling customers, they need all these stronger metals. Then we see these universities. Now in the universities, we have two types of universities, we have the workforce development university trying to train the next generation technicians and we also see research universities. With a 200G we're able to give a research university a large range of printer performance, so they are able to do anything from 400 Watts, research studies, and also with single laser, but also look at two lasers, and study the interaction of two lasers working together. And now, we also see, particularly with copper, electromobility is getting a lot of attention. 3D printed parts are perfect for that type of applications, so we're seeing a lot of focus into electromobility and copper printing, both in heat exchangers as well as 3D antennas.

TCT: What is Xact Metal’s approach to materials development?

JMG: We mostly do it ourselves, we have a recipe that we go through. But of course, we'll partner with a customer that wants to do some of that on their own and help to kind of speed up development. We do it ourselves, we believe that we can do the parameters for general applications, but we also believe that customers know better what is needed for their application. So, we'll ask an experienced customer to kind of start - we like to say an experienced customer because we don't want a young customer to start with this journey - we want an experienced customer to then be able to tweak the performance of the printer parameters to achieve that extra level of performance they can with matching it to their application.

TCT: When we spoke at TCT 3Sixty, you told me there is a bigger Xact Metal 3D printing system coming next year – Is that in response to demand from the industry and users you work with?

JMG: We just see that, of course, there's a need for either putting more parts within a build plate. Typically when this machine comes into a customer the demand immediately fills the machine so what we find this is when this comes into a tooling shop the machines immediately gets loaded so we find that customers want to print not necessarily bigger parts but just more parts within the build plate and they need to do at an affordable price point or we find that people need to print bigger parts and so we like the size of 125 and 150 a lot, I think many parts fit there, but of course there's a need for larger volumes and we think a sweet spot for that is a roughly 300mm cubed. That's a nice size for us, a mid sized machine at a very attractive price point.

Want to discuss? Join the conversation on the Additive Manufacturing Global Community Discord.

Get your FREE print subscription to TCT Magazine.