Catastrophic residential fires and wildfires have a significant impact in terms of fatalities and injuries, as well as loss of property.

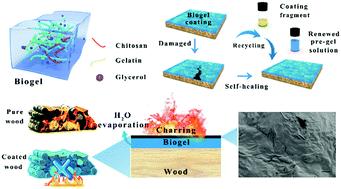

Currently, scientists illustrate a new kind of coating designed to restrict the flammability of wood employed in construction, possibly offering additional time to escape fires and also hindering its spread. The eco-friendly flame retardant could also be applied to other flammable materials, like polyurethane foam, textiles and three-dimensional (3D)-printed parts.

The scientists showcased their results at the spring conference of the American Chemical Society (ACS). ACS Spring 2022 is a hybrid conference being held in-person and virtually between March 20thand 24th, with on-demand access available between March 21stand April 8th. The meeting covers over 12,000 presentations on a broad range of science subjects.

According to the National Fire Protection Association, home fires make up the bulk of fire deaths and result in billions of dollars in property damage annually. Fitting smoke detectors and fire sprinklers can help, but another method is to make building materials less flammable. That is the aim of Thomas Kolibaba, Ph.D., who is creating a new coating for these materials.

This type of treatment, which could be deposited via dipping, spraying or pressure treatment, could make homes much safer. The coating could reduce flame spread and smoke production, which could limit damage and give people more time to evacuate.

Thomas Kolibaba, Ph D, Graduate Student and Postdoctoral Researcher, Grunlan’s Lab, Texas A&M University

In contrast to the majority of existing fire retardant treatments, its constituents are environmentally friendly, and it might also be priced less, observes Jaime Grunlan, Ph.D., the principal investigator of the project.

Kolibaba performed the research as a graduate student and postdoctoral researcher in Grunlan’s lab at Texas A&M University, developing on the polyelectrolyte coating technology conceived by the team in 2009 and later improved by other scientists.

Many of these coatings are created by dipping material or other things in a solution comprising one polymer with plenty of positive charges on it, which is then followed by a soak in another solution comprising a polymer with plenty of negative charges, and then going over these steps again and again to attain the preferred thickness.

The opposing charges attract the polyelectrolyte molecules in the alternating layers together into complexes on the surface of the item, developing a coating that can quench a flame.

Kolibaba was keen to spread this treatment to wood, but the multistep method was not achievable for producers because wood requires a long time to absorb these chemicals. Through additional research, he adapted another Grunlan method and was able to bring down the steps to two: one dip for coating the wood and the second dip in a diverse solution to treat the coating by switching the pH.

However, that second solution kept becoming a sticky mess, so the restructured process still was not suitable for consumer or industrial applications.

In the most recent alteration, which will be demonstrated at ACS Spring 2022, Kolibaba overcame that issue with a process that he states would be easy for consumers or industry to adopt.

He soaked plywood in an aqueous solution comprising the monomer hydroxyethyl methacrylate phosphate (HMP), the positively charged polymer polyethylenimine (PEI) and a photoinitiator called TPO.

Rather than dipping the wood for a second time into a solution to cure, he placed it under ultraviolet (UV) light for a few minutes. That made TPO change the HMP into a negatively charged polymer, which then developed a polyelectrolyte complex with PEI. The subsequent coating was transparent and just a few micrometers in thickness, so it did not alter the appearance of the wood and only marginally added to its weight.

The treated wood, in lab flame tests, decreased the amount of heat emitted during burning and quickly developed a surface layer of char that safeguarded the underlying wood — properties that could curb fire spread and damage.

It also reduced smoke production by 56%, an unusually large degree.

Thomas Kolibaba, Ph.D, Graduate Student and Postdoctoral Researcher, Grunlan’s Lab, Texas A&M University

In contrast to the team’s previous coatings, which are linked together by ionic bonds, this coating is covalently bonded. So, Grunlan supposes it to be water-resistant — and thus durable — and perhaps also antifungal and water-repellent.

Industrial users could apply the coating on building materials, like wooden studs and other framings, or oriented strand boards (a kind of engineered wood akin to particle board). Residential property holders could use a backpack sprayer to safeguard current structures like barns or fences, which have been established to spread wildfires, Kolibaba states.

Other possible applications include polyurethane foam and textiles for home furnishings, clothing and the aviation and automotive sectors, Grunlan states.

The UV-curable polyelectrolytes could also be employed as a resin to create 3D-printed components, which are flammable when produced using traditional resins, Kolibaba adds. That could be predominantly advantageous in the aerospace domain, for example, the International Space Station, he observes.

The scientists acknowledge funding and support from Texas A&M University.

New Lightweight Coating to Reduce Wood Flammability