Markforged, creator of the integrated metal and carbon fibre additive manufacturing platform, The Digital Forge, is advancing its position as a leader in point-of-need production of industrial-strength end use parts with the FX20 printer.

This new production-ready hardware prints the flame-retardant, high-performance thermoplastic material with ULTEM 9085 filament in combination with Markforged’s propriety Continuous Fibre Reinforcement printing technology for high-strength, heat resistant and higher performance parts that can meet the needs of the most demanding industries.

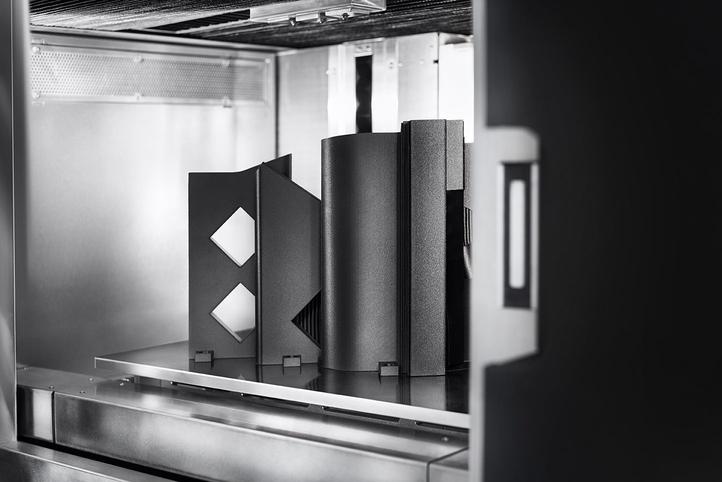

Built to scale distributed global production, the FX20 is precision-designed and sensor-driven to deliver high accuracy, quality and reliability to fabricate parts directly at the point-of-need with the simple click of a button. As the biggest, fastest and smartest 3D printer Markforged has ever produced, the FX20 pairs size and throughput to make larger parts at high speeds.

This new technology, alongside high-temperature printing capabilities, elevates the Digital Forge platform from accessible industrial-strength composite manufacturing to robust production applications. The FX20 has a heated build chamber capable of maintaining up to a 200°C temperature and the capacity to print parts up to 525mm x 400mm x 400mm in size. The FX20 is up to eight times faster than the default print settings on Markforged’s existing line of composite printers and prints nearly five times larger builds than its next largest printer, the X7.

Bringing together ULTEM 9085 filament with Markforged’s proprietary Continuous Fibre Reinforcement technology will help manufacturers move from augmenting manufacturing operations with composite 3D printing to replacing entire segments of the supply chain by bringing strong, accurate parts that solve demanding, end-use applications right where needed.

Printing the ULTEM 9085 filament with Continuous Fibre Reinforcement expands the advantages manufacturers can realise through additive technology. Adding the FX20 to the Digital Forge platform addresses a broader set of needs and applications.

“Markforged continues to build on our innovative legacy and lead the way in composite 3D printing - the future of manufacturing. With the releases of the FX20 and Continuous Fibre Reinforced ULTEM 9085 filament, we’re now fulfilling that promise to manufacturers who previously, in the most demanding environments, were unable to experience the benefits of the Digital Forge and our unique materials,” said Shai Terem, president and CEO of Markforged. “By helping move composites toward robust production, we’ll unlock more functional parts, made of stronger materials of even more impressive size, with applications from the factory floor to flight.”

The FX20 and ULTEM 9085 filament are expected to ship worldwide in the first half of 2022. Formnext attendees can see the printer at Markforged’s booth from November 16-19. For more information, visit https://3d.markforged.com/get-updates-on-FX20.html.