After designing and manufacturing a range of micro- and small gas turbines, Cape Aerospace Technologies (CAT) is developing a range of new products, including larger turbojets and a rocket.

David Krige, Managing Director at Cape Aerospace Technologies, revealed this in a presentation at the Virtual Aerospace and Defence Industry Day held on 22 February. The Day was organised by the Department of Trade, Industry and Competition’s Aerospace Industry Support Initiative (AISI), which has provided assistance to CAT.

Cape Aerospace Technologies emerged from Baird Micro Turbines, which was established in 1998. CAT has built three small gas turbines producing 12, 25 and 46 kg of thrust for use in model aircraft, high speed target drones, unmanned aerial vehicles, experimental aircraft and full-size gliders.

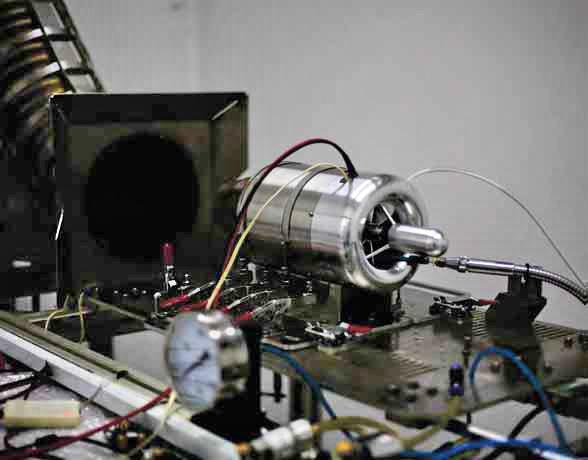

The CAT 120 develops 120 N (12 kg) of thrust; the CAT 250 produces 250 N, and the CAT 400 produces 460 N of thrust. CAT 120 and CAT 250 engines have been delivered to international customers, including in the Middle East and Europe, such as the United Arab Emirates and Turkey. The latest CAT 400 engine, which developed more thrust than the rated specification, is currently going through the industrialisation and production phases – Cape Aerospace Technologies has received pre-orders for this engine.

All these engines are light, weighing 1.4, 1.9 and 3.6 kg respectively. All can operate between -25 and 50 degrees Celsius and at altitudes of up to 8 000 metres. They are intended for sub-sonic applications and can operate on diesel, kerosene or Jet A1 fuel.

Krige explained that as tolerances are high and quality control is tight, CAT uses top-end machinery. In-house manufacturing equipment includes CNC turning, milling, grinding and routing machines; turbine balancing equipment; an ultrasonic cleaner; 3D resin printer; and 3D filament printer to mention a few. The company is growing towards owning several five-axis machines. Turbine-related ancillaries, software and associated electronic control systems are designed and developed in-house – turbines make use of FADEC (full authority digital engine control).

CAT also has the ability to design and manufacture composite airframes, mainly for the hobby industry. In the 2000s it built a target drone for the South African Navy, and the composite airframe as well as telemetry, comms and turbines were designed and manufactured in-house.

Not content to rest on its laurels, Cape Aerospace Technologies is now working on the CAT 800, developing 800 N of thrust, and the CAT 1400, developing 1 400 N of thrust. It is also working on a 1 kN rocket – Krige explained that this will be tested soon. The idea is to scale the rocket up so that it will eventually be capable of reaching low earth orbit (LEO).

Various future projects and ambitions include a vertical takeoff and landing passenger aircraft (air taxi), auxiliary power units (APUs), turboshafts, turboprops, turbofans and range extenders. Some of this is in response to the many requests for gas turbines for power generation rather than propulsion.

Another project is for a twin 250 N mount, intended for a jetwing (such as flown by Jetmen like Yves Rossy). With a twin mount under each wing, total thrust is 1 000 N. CAT is developing the jetwing’s propulsion system for a client and hopes to carry out a launch from Swellendam. The client intends to scale the twin configuration to using 400 N engines.

Krige said Cape Aerospace Technologies is the only micro to small turbojet manufacturer in Africa – all design, manufacture and testing is done in-house. The company saw a gap in the African market for small gas turbines and has cornered this market. Its successes have seen multiple export sales, including an exclusive sales agreement with an international client.

Cape Aerospace Technologies has recorded a number of highlights over the years, and these include developing a target drone for the South African Navy in the 2000s, developing the first single fuel electric start system for micro gas turbines in the world in 1999, developing the world’s first plasma ignition system for micro gas turbines (outperforming standard glowplugs), and developing the first fully web-enabled gas turbine user interface with over-the-air update capability.

CAT boasts the fastest micro turbojet startup time on the market: six seconds from 0 rpm to idle (32 000 rpm), compared to the industry’s best at 25-40 seconds. Going from idle to full throttle takes three seconds.

The Aerospace Industry Support Initiative (AISI) has provided financial support to CAT, specifically on the CAT 250 and CAT 400 engines, and helped developed engine control software. As such, CAT is one of the AISI’s biggest success stories. The AISI is an initiative of the Department of Trade, Industry and Competition and managed and hosted by the Council for Scientific and Industrial Research (CSIR). The CSIR, together with Stellenbosch University, collaborate with CAT to support industry and students.