At the Technical University of Denmark (DTU), a team of researchers have developed a new kind of 3D printer whose technology combines a CT scanner and light. By reversing the principle of CT scanning, they could create all types of parts in record time from different polymer resins and play on their hardness. They would thus be able to reproduce the appearance of blood vessels or muscle tissue.

Today’s CT scans allow us to make slice images of our body parts and to visualize tissues of different densities. This X-ray machine is therefore used in the medical sector to establish a diagnosis. In this case, it was used to design a new, faster resin 3D printer.

Assistant Professor Yi Yang is behind this project (photo credits: DTU)

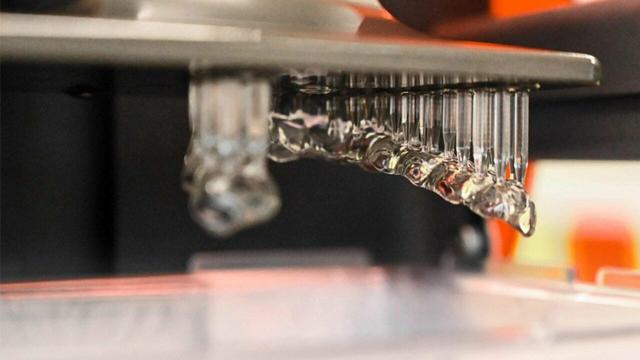

Yi Yang is an assistant professor in DTU Chemistry and was involved in this project. He explained, “Our printer will build a physical object at the intersects of computed tomographic images. The technology enables us to build 3D objects embedded with different properties and material transitions. We use a method called Tomographic Vat Photopolymerization (TVP), which allows us to print all points in a 3D object simultaneously. One has to imagine a box containing a liquid polymer – a kind of polymeric printer ink. By exposing the ink to light of certain wavelengths, determined by a 3D image and built up as a CT scan, the ink turns solid in the desired shape.”

In concrete terms, the machine uses an inverted CT image as a model and transforms the resin using light rays. This process would be much faster than laser technology because it solidifies the whole resin according to the desired shape instead of doing it point by point. It could also vary the flexibility of the part in question according to the computer model, by directly controlling the wavelengths of the light used. This new machine would therefore be faster and offer more possibilities in terms of materials.

So far, the tests are very conclusive and many different geometries have been realized. However, the team sees huge potential in the field of bioprinting: by playing with the flexibility of the material, they could imagine vascularized parts for patients who need new tissues and organs. Yi Yang concluded, “The degree of detail and flexibility in our 3D printing will hopefully be so extensive that the technique can be used to produce fully vascularized constructs using biopolymers as ‘ink’. This technology might be able to replicate the softness and unique build-up of blood vessels, capillaries, and muscles. There is a long way to go, but hopefully the printer can bring us closer to the goal.” You can find more information in the official press release HERE.

What do you think of this new 3D printer that combines a CT scanner and light? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Prototype Hubs