In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

First of all, voting is now open for the 3D Printing Industry Awards.

Today’s edition features MES software partnerships, system installations, build chamber advances, an upcoming Indian 3D printing facility, and everything from additive manufactured cars to toys, and an incredibly-realistic eyeball model.

Read on for the most recent updates from the DMC, 3D Metalforge, Addion, 3DPRINTUK, Teton Simulation, Laser Lines, Objex, Morf3D, Anycubic, Elegoo and more.

AM gongs awarded, including ‘Best of British’

Starting this week on a positive note with AM awards, 3D printing service provider 3DPRINTUK has won the ‘Business Reporter Best of British’ competition. Hosted by UK newspaper the Independent, the contest seeks to recognize economically-successful SMEs, while generally promoting businesses that highlight the diversity of ‘brand Britain.’

“While we have been working with 3D printing technologies for many years, we are aware that there are many companies that do not fully understand the potential of 3D printing,” said Nick Allen, MD of 3DPRINTUK. “Our Best of British Business award video (above) gives us a highly accessible way of explaining the possibilities that exist through the use of 3D printing in terms of innovation.”

Elsewhere, 3D printing bureau 3D Metalforge is celebrating a different kind of success, having been recertified by Lloyd’s Register for the DED and LPBF 3D printing of parts using various alloys. The firm’s ‘LR-TWI’ accreditation essentially verifies that its facilities, equipment and processes meet lofty industry standards, while its products fulfil quality assurance and safety-related legal requirements.

As one of only seven organizations to have received the certification, which covers the reception, storage and handling of feedstock, as well as 3D printing processes and build control, the firm says that its customers now stand to benefit from the high efficiency, reliability and part quality levels that striving for the award entails.

“We continue to work to provide greater value to our customers,” said Matthew Waterhouse, MD of 3D Metalforge. “This certification supports our relationships with partners, many of whom are large international firms requiring these qualifications, and the certification is also expected to widen our exposure to commercial opportunities with future customers.”

This week, ceramic 3D printing specialist Lithoz also has cause for revelry, as it’s celebrating the tenth anniversary of its foundation. To commemorate the occasion, the firm has pledged to pay tribute to its team and their successes through a series of stunts and events, including ‘best-of’ videos, logo changes and a rebranded ‘Lithoz Happy Birthday Hour’ networking event, on September 15, 2021 at 6pm.

Looking to the next ten years, Lithoz has stated that its goal is to “ensure that the rest of the manufacturing world knows the unimaginable power of its production technique.” This sentiment has been echoed by its CTO Johannes Benedikt, who said that it now aims to “implement 3D printing on an ever-larger industrial scale, and further strengthen its position as the number one choice for newcomers.”

Stratasys, Objex find new applications

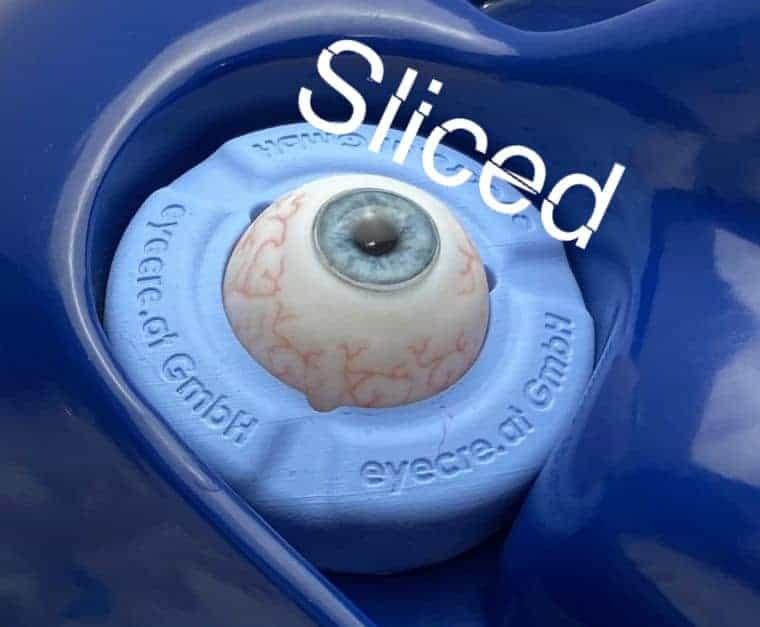

Austrian 3D printing bureau Addion has used Stratasys’ J750 Digital Anatomy system to manufacture novel, unsettlingly-realistic, eye surgery models. Produced on behalf of medical training product provider Eyecre, the true-to-life optical replicas are set to be marketed to pharma firms, which in turn, use them for both product testing and staff tuition.

Thanks to the J750’s full-color capabilities, the Addion team have been able to develop models that accurately recreate the soft, watery tissue of the eye, in which the cornea can be detached and reattached, their skin layer is just a tenth of a millimeter thick, and instruments can be used to perform fine surgeries on them with extreme precision.

“Companies like Addion perfectly demonstrate the capabilities and potential of the Digital Anatomy Printer,” explains Arnaud Toutain, Stratasys’ Healthcare Sales and Development Lead for EMEA. “Through the ultra-realistic eye models that they are developing, we are seeing new possibilities in ophthalmic 3D model precision and complexity.”

Over in Canada, 3D printing service provider Objex Unlimited has also begun addressing a new application with its technologies, having struck a partnership with toy firm Little You. Designed to allow children to create custom figures online, Little You’s unique toy offering will now be brought to life by Objex, which has agreed to 3D print them using Mimaki systems, before shipping them around the world.

“We already offer two materials, the Full-Color Sandstone, the Full-Color Glass Fiber Composite, and now we are adding the Full-Color Acrylic Resin from Mimaki,” said Christina Guo, Founder of Little You. “With three advanced 3D printing technology, we can create unique, vibrant, and highly personalized toy figures that are inhibiting your child’s imagination into real life.”

“Little You is making a breakthrough by bringing this industrial technology into the realms of the children’s toy market.”

Eco-friendly AM Hub and XEV advances

Sustainable production has taken two steps forward this week, with Denmark’s AM Hub forming a new alliance, and the unveiling of XEV’s ‘YoYo.’ In the case of the former, cloud product development workspace Wikifactory says that it has partnered with the AM Hub to “transform global manufacturing,” and enable “almost every product imaginable to be sustainably made for the next 100 years.”

In practise, the firm aims to achieve this by leveraging a new model developed by the Danish AM Hub, in which companies can calculate the exact CO2-savings they stand to make by switching to 3D printing, to establish an “Internet of Production,” that makes product innovation and R&D easier, faster, cheaper and less damaging to the environment.

“Despite the development of digital production and Internet-based services, the manufacturing industry has still not had its major transformation,” said Nicolai Peitersen, Co-founder of Wikifactory. “Joining forces with AM Hub’s diverse network was a huge driver for us to move our headquarters to Denmark, and we’re delighted not just to partner up, but to move in together this year.”

The YoYo electric vehicle, meanwhile, made an appearance at the International Motor Show in Germany last week. Set to be built using a ‘3D printing production line,’ the Renault Twizy-like car features keyless entry, a large touchscreen ‘infotainment’ system and power mirrors, while in terms of range, it’s capable of running for 93 miles on a full charge.

To fund the YoYo’s launch, Italo-Chinese start-up XEV set up a Kickstarter in February, in which it claimed the vehicle would “combine smart urban mobility with industrial AM,” and though the car has reportedly failed to meet its €500,000 target thus far, if it does make it into production, it’s set to be marketed in Italy at prices starting from €13,900.

Nanotube, jewelry resins announced

3D printer manufacturer B9Creations has partnered with nanomaterial specialist Mechnano to expand on its photopolymer offering. Leveraging B9Creations’ high-throughput, B9 Core machines and its proprietary carbon nanotubes, Mechnano has now committed to delivering “high-value materials, engineered to meet specific performance requirements.”

“The decision to partner with Mechnano was a natural step in expanding B9Creations’ offering of production-ready AM solutions,” explains Shon Anderson, CEO of B9Creations. “Mechnano’s engineering-grade materials are well-matched for the high throughput, precision, and plug-and-play technology of the B9 Core, to enable businesses to move from prototyping to production with ease.”

German resin developer MACK4D has also announced a material update, with the launch of its eco-friendly new TIKO-G polymer. Formulated specifically to address jewellery casting applications, the resin is said to be compatible with most Asiga, DLP or LCD 3D printers, while more than 25% of its composition is made up of sustainable raw materials.

According to the company, the TIKO-G yields “dimensionally-stable” parts “no matter when you embed the print model,” but jewelry pieces particularly impress due to their “smooth and true to detail surface.” The materials are available to purchase now via MACK4D’s store, at prices starting from €99 for 500 grams of the resin in a ‘red wine’ color, with the firm offering a 10% discount on initial orders.

Teton, AMFG launch software updates

3D printing program developer Teton Simulation has unveiled its latest software product: SmartSlice for BCN3D Stratos. Developed specifically to allow the BCN3D users to eliminate costly print-test-redesign cycles, as well as ensuring printed parts perform as expected, the add-on features a custom optimization tool, which enables them to minimize their print time and overall material usage as well.

According to the firm, this provides users with a higher ROI on their projects, and while savings vary, it says the average SmartSlice user reports a reduction of at least 30% in materials needed. The software’s database also supports many BCN3D filaments, allowing users to virtually qualify them prior to purchase, and a free trial of the program will now be pre-installed within each Stratos download.

“Teton Simulation’s SmartSlice is an innovative tool that really empowers its users to unlock cost and time-effective, functional 3D printing.” said BCN3D CTO, Eric Pallarés. “It really matches BCN3D’s mission to provide solutions to change how the world is made, so it was a no-brainer decision to integrate SmartSlice into BCN3D Stratos.”

In other software news, MES program developer AMFG has agreed to become part of Stratasys’ GrabCAD Software Partner Program. Having joined, the firm’s workflow automation system will now be integrated into Stratasys’ FDM systems and GrabCAD platform, enabling users to enter serial production, while collecting critical build data to ensure they achieve repeatable part quality.

“AMFG has demonstrated a compelling vision for AM execution, along with a robust solution that is positioned to help our joint customers manage and scale their operations,” said James Berlin, GrabCAD Senior Product Manager at Stratasys. “We’re proud to include them in the GrabCAD Software Partner Program, and look forward to the ability to jointly provide connected capabilities to the industry.”

SEDAXIS to establish AM facility

Indian engineering college VIT Chennai has signed a memorandum of understanding (MoU) with SEDAXIS Advanced Materials to establish a Centre of Excellence (CoE) for Additive Manufacturing. Set to be sited on VIT Chennai’s campus, the proposed facility will be equipped with 3D printers across multiple technologies, so that it can be used to boost the manufacturing capabilities of the region’s SMEs.

Initially, the center’s dedicated research arm’s will focus on continuous composites R&D and working on open material and parameter machines, before progressing into product development, with the aim of accelerating 3D printing’s adoption within India’s automotive, aerospace, defense, manufacturing, and consumer goods sectors, among others.

“VIT has always been the frontrunner in closely collaborating with the industry,” said Dr. Kanchana Bhaaskaran, Pro-Vice-Chancellor at VIT Chennai. “Besides providing solutions to the social and industrial problems, we are looking forward to witnessing remarkable outcomes as part of this association in terms of supporting academic research and projects.”

“Today, we are excited to welcome on board SEDAXIS Advanced Materials, the industry partner, in our journey of fruitful collaboration in the domain of AM.”

3D printer R&D and funding advances

Starting off this week’s bumper machine update with SLM Solutions, the German 3D printer manufacturer has agreed to install two SLM 500s and an NXG XII 600, at Morf3D’s Applied Digital Manufacturing Center. Once fully-fitted in 2022, the systems will support Morf3D in its quest to improve lead times, order flexibility, cost efficiency and quality for its clients.

In addition to the installation, SLM Solutions will also offer on-site support in the form of education, training, and consultation, which according to Morf3D’s CEO Ivan Madera, will allow its R&D team to “accelerate the qualification process” by collaborating on application development and part certification within the aerospace, space, and defense markets.

“Our partnership with SLM Solutions dramatically shifts the landscape of serial production, enabling our customers to achieve unmatched levels of quality and performance,” said Ivan Madera, CEO of Morf3D. “The NXG XII 600 platform is an engineering marvel that addresses many aspects of a production-ready system, and the ADMC will enable new industry partnerships, significantly scaling AM.”

Likewise, UK 3D printing bureau Laser Lines has announced the installation of the country’s first Stratasys J35 Pro at its Banbury facility. The machine is currently being showcased to designers and engineers there, demonstrating both its appearance and functionality in the pre-production stage, and according to the firm’s Sales Director Mark Tyrtania, the machine is already attracting “a lot of interest” from clientele.

Alongside its J35 Pro fitting, Laser Lines has also unveiled a strategic partnership with the Digital Manufacturing Centre (DMC). As part of their collaboration, the UK’s first Stratasys F770 will be installed at the DMC, in a move that is designed to aid its partners in the automotive, aerospace and medical sectors, while allowing Laser Lines to exhibit the system to clients in a ‘live manufacturing environment.’

“Our partnership with Laser Lines is an integral part of this pursuit, providing us with state-of-the-art AM equipment backed by exceptional support,” said DMC CEO Kieron Salter. “This new Stratasys F770 will be a significant boost to our FDM capability and capacity. We look forward to learning more about the machine and putting it through its paces in a live production environment.”

In other DMC-related news, the center has announced that it will be one of the first to receive Renishaw’s new RenAM 500 Flex machine. As a long-term Renishaw partner, the DMC has been selected as a beta site for the system’s ‘in-industry’ testing. Forming one of the machine’s final R&D phases, the program will see the DMC verify its capabilities in a busy commercial production environment.

The printer itself features the same build chamber as the RenAM 500, but combines it with a non-recirculating powder system. This, in addition to Renishaw’s new ‘material change kits,’ enables users to complete a material change in just 8 hours, while minimizing material loss between transitions. Set to be available in single and quad-laser layouts, the platform will be launched at Formnext later this year.

Finally, desktop 3D printer manufacturers Anycubic and Elegoo have made rapid starts to their respective Kickstarters for new machines. With its upcoming Photon Ultra system, Anycubic managed to raise nearly $2 million inside of 24 hours, while Elegoo’s Jupiter 6K Mono machine smashed its $100,000 target in the same time, raising nearly $4 million.

More information about the 3D printers’ capabilities and respective campaigns can be found via Anycubic’s Photon Ultra and Elegoo’s Jupiter Kickstarter pages.

3D printing R&D breakthroughs

Finishing this week with the latest in AM R&D, particle extraction technology developer BOFA International has announced the creation of a novel means of making filter exchanges during metal 3D printing, safer and more productive.

Known as the ‘AM 400,’ the firm’s new system enables filters that remove potentially harmful fumes and particles to be exchanged on-site, without risking a thermal event or having to cease production. With a high air flow potential of up to 190 cu ft/min, the unit also optimizes filter performance, enabling operators to monitor the filter’s status and coordinate exchanges to match their maintenance schedules.

“This innovation in filtration design will lead to significant productivity gains for businesses involved in metal AM,” said Haydn Knight, Sales & Marketing Director at BOFA. “This production process is used across multiple industry sectors to create high value components and products, and by enabling easier and safer filter exchange, end users are able to benefit from reduced downtime.”

Working with 3D printer manufacturer EOS, chemical specialist Linde Group has made an R&D discovery of its own, by identifying how oxygen influences machines’ build chambers during production, particularly when processing AlSi10Mg.

During the study last year, Linde used an EOS M 290 system to process the alloy 21 times with varying residual oxygen concentrations ranging from 1000 ppm to 5000 ppm. By deploying its ADDvance technology, the firm found that it was able to achieve more precise measurements, that allowed the machine’s sensors to be mapped, and more consistent oxygen levels to be delivered to its build chamber.

“For EOS, a consistent and reliable gas atmosphere, as well as accuracy of oxygen gas readings, is vital for us because it is vital for our customers,” said Dr. Astrid Rota, Head of Metal Process Technology at EOS. “Some industries require not only the most advanced printing systems generating best material quality, but also need to record highly detailed data which is where ADDvance O2 precision really delivers.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Eyecre’s 3D printed eye model ‘looking at’ the Sliced logo. Photo via Stratasys.